Smallaire extends the harvest window with their leading Grain Aeration Systems.

Smallaire is a family-owned business that specialises in providing air movement systems for agricultural, commercial and domestic clients.

From its beginning in 1974, the company has grown to become an award-winning manufacturer and exporter that prides itself on its dedication to innovation and quality.

From its base at Horsham VIC in the grain growing Wimmera region, it was almost inevitable that Smallaire would find itself providing aeration systems for grain storage.

Today, the company’s grain aeration systems can be fitted to new or existing silos, either elevated or flat-bottomed, and provide users with the ability to dry and cool grain as well as prevent insect infestation.

The knowledge that grain can be dried successfully in the silo provides growers with a greatly extended harvesting window.

Grain can be brought in earlier in the season as even if there are some green patches in the crop, with higher moisture content, there is no risk of spoiling.

Jock Baker the General Manager of Smallaire is shown here with the grain drying and aerating blower kits that has helped many grain growers achieve higher prices for their grain

Growers can also take advantage of earlier starts in the day to harvest and keep going longer into the night.

If a storm is on its way, the decision can still be made to get the crop off with the confidence it can be dried later in the silo.

In addition, harvesting grain with higher moisture content assists in the cooling cycle as it is the same principle as an evaporative air conditioner, but in this case with the grain acting as the wet filter.

The presence of insects and vermin will also be minimised (possibly even eliminated) and chemicals are not required to keep insects out.

Smallaire grain drying and aerating blowers feature strong pressed steel casings and a

durable hot-dipped galvanized finish (a powder coating option is available upon request).

Units are lightweight and manoeuvrable and balanced to prevent vibration.

A single fan can be moved around a number of sites to save on the cost of multiple blowers

Smallaire grain drying and aerating blowers feature strong pressed steel casings and a durable hot-dipped galvanized finish (a powder coating option is available upon request).

Units are lightweight and manoeuvrable and balanced to prevent vibration.

A single fan can be moved around a number of sites to save on the cost of multiple blowers.

Diesel fired heaters are also available for faster drying.

Fans are also covered by a 12-month warranty.

In an elevated silo, air is first forced downward from the plenum to the base of the silo cone, and then rises upward and is distributed evenly throughout the silo for consistent drying and aeration

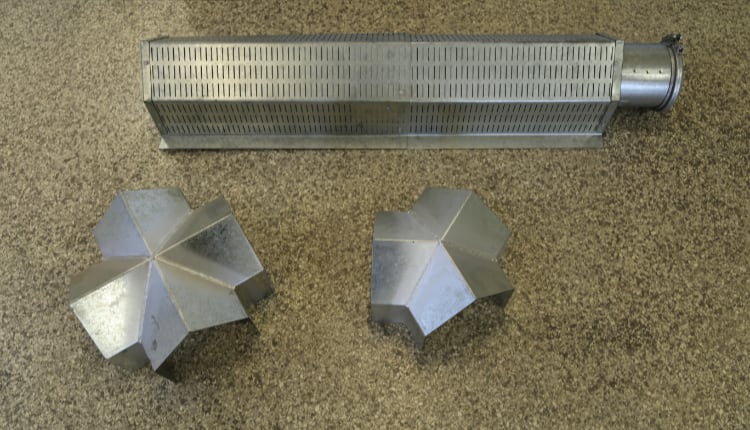

The other half of the Smallaire system is the galvanized steel plenum fitted horizontally across the bottom of the silo.

When the silo is filled, the void underneath the v-shaped plenum remains as open air space and acts as the conduit for the introduction of fresh air flow from the exterior fan.

In an elevated silo this air is first forced downward from the plenum to the base of the silo cone, and then rises upward and is distributed evenly throughout the silo for consistent drying and aeration.

For flat-bottomed silos, perforated flat floor ducting takes the place of the v-shaped plenum and air is forced directly upwards through the perforations.

Multi-silo systems with a single blower can also be set up with the use of manifold ducting so that individual silos can be turned on or off at any time.

Galvanized steel plenums are fitted horizontally across the bottom of the silo. When the silo is filled, the void underneath the v-shaped plenum remains as open air space and acts as the conduit for the introduction of fresh air flow from the exterior fan

Rounding out the Smallaire system are air temperature and humidity controllers.

The controllers allow growers to set humidity and temperature for drying grain in the best climatic conditions. Dials can then be reset for aeration to blow cold, dry air through the grain.

These units take the guesswork out of grain drying and allow growers to get on to other jobs while the fans are monitored by the controller.

Smallaire claim to stock the most inexpensive controller on the market and the only one with the humidity and temperature functions all in one. The unit is fully portable and only the size of a shoe box.

An extension to the Smallaire aeration system is the inline fumigation cabinet. Ideal for use with existing fans, these units hook in-line with an existing system for minimal fuss and an easy setup.

With this system, phosphine tablets are placed in the Fumigator cabinet tray provided and once the tablets are spent, the powder form drops through the mesh grate ready for easy disposal.

An added advantage is that no residue is left in the grain.

Smallaire also provides easy to install temperature probe kits that can be fitted to any silo to provide a digital readout of the internal temperature without the need to enter the silo.

The probe also measures the ambient external temperature and humidity so users can decide when to turn blowers on or off.

As well as its grain aeration systems, Smallaire’s air movement expertise is also in hot demand for airseeder setups.

The company provides blowers, components and an exclusive Airseeder CAD (Computer Aided Design) design program to aid in the design of systems to meet individual needs.

The program ensures the matching of the correct sizes of feeder hoses, correct Primary and Secondary head and Pressurized box systems, fans and venturi.

For more information call Smallaire on tel: 03 5382 5688, email us here

Easy to install temperature probe kits can be fitted to any silo to provide a digital readout of the internal temperature without the need to enter the silo

For flat-bottomed silos, perforated flat floor ducting takes the place of the v-shaped plenum and air is forced directly upwards through the perforations

Multi-silo systems with a single blower can be set up with the use of manifold ducting so that

individual silos can be turned on or off at any time

Controllers allow growers to set humidity and temperature for drying grain in the best climatic conditions. Dials can then be reset for aeration to blow cold, dry air through the grain

An extension to the Smallaire aeration system is the inline fumigation cabinet.

Ideal for use with existing fans, these units hook in-line with an existing system for minimal fuss and an easy setup